Technical Consulting: Provides customers with filtration technology advice. Based on the customer's industry characteristics and operating conditions, we introduce suitable metal filter types, materials, and filtration principles, helping customers understand product performance and applicability.

Model Selection: Based on the customer's requirements for filter media, precision, flow rate, operating temperature, and pressure, we recommend appropriate metal filter models or provide customized selection solutions to ensure the filter meets actual application needs.

Design: For customers with special requirements, we provide free customized solutions to design filter structure, dimensions, connection methods, and other aspects. We also use simulations to predict filter performance.

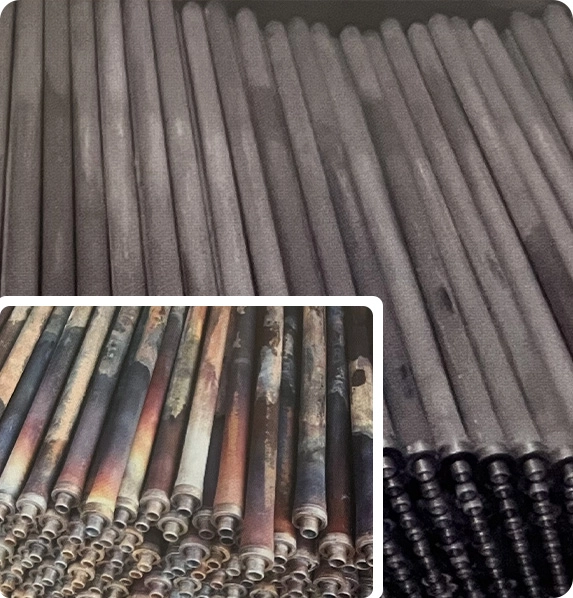

Backwashing service: Stainless steel filter elements have strong durability and can be cleaned by backwashing (reverse water flow). Providing this cleaning service can extend the service life of the filter element and ensure its long-term efficient operation.

Ultrasonic cleaning: Use ultrasonic technology to thoroughly clean the surface of the filter element to remove stubborn impurities or sediments, suitable for precision filtration systems.

Regeneration service: For some reusable filter elements, provide regeneration services for decontamination, desorption and restoration of their filtration effect.

Customized Production: Customizes metal filters according to the customer's confirmed plan. We strictly control the production process and quality to ensure that the product meets design requirements. We also provide services such as rapid prototyping.

Progress Tracking: Assigns a professional project manager to monitor the production progress throughout the process, provide timely feedback to customers on the filter production status, keep customers informed of the order fulfillment status, and promptly communicate and coordinate any special circumstances such as delays.

Installation and Commissioning Guidance: After filter delivery, we arrange on-site installation and commissioning guidance based on customer needs to ensure proper installation and proper operation of the filter. We also provide operational training for the customer's production staff.

Filter Element Replacement: We provide filter element replacement services based on filter usage and customer needs to ensure optimal filtration performance. We also offer filter elements in various materials and filtration filtration ratings.

Performance Testing: We provide laboratory testing services, conducting comprehensive filter performance testing, such as filtration accuracy testing and pressure resistance testing, to help customers understand the filter's performance and provide a basis for maintenance and replacement.

Consumables: We provide genuine filter-related accessories and consumables, such as filter elements and seals, to ensure quality and compatibility, meeting customers' daily maintenance and replacement needs.

Repair and Maintenance: We provide filter repair and maintenance services, regularly inspecting and maintaining the filter, and promptly addressing any operational faults, such as replacing damaged filter elements, seals, and other components, to ensure long-term, stable operation.

Complaint handling: Establish a comprehensive complaint handling mechanism, respond quickly to customer feedback, promptly arrange after-sales service personnel to rush to the site to resolve issues, collect customer feedback on product quality, usage conditions, etc., and continuously improve service quality.